Industries Served: Industrial Vibration Monitoring

Industrial vibration monitoring is a great help to the chemical processing industry, as it relies heavily on rotating machinery. As a result, fan, blower, compressor, turbine, pump, chiller, and motor monitoring services can protect a manufacturers production schedule and bottom line. VSC has solved this industry’ problems since its inception. Our latest products and industrial vibration analysis techniques continue to offer the greatest solutions for machine reliability.

Facilities Management

The life blood of every facility is its machinery. Therefore reliable industrial vibration monitoring services and plans for pumps, fans, air handlers, compressors, motors and chillers are paramount. VSC’ continuous monitoring plans and problem solving actions enable our clients‚Äô facilities to operate proactive maintenance so they resolve machinery issues early with limited costs.

Compressors of all sizes, shapes and power are utilized in this industry for compressing all types of gases. These compressors are huge power consumers and, in many cases, the gases can become very dangerous if not handled well. VSC has been at the forefront of technology for compressor monitoring for many decades, all the while continually upgrading our technological capabilities.

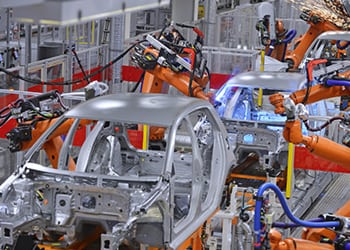

Industrial Manufacturing

Industrial manufacturers’ success depends on the reliability of machinery such as motors, pumps, rolls, compressors, chillers, fans, air handlers, and extruders. When equipment breaks unexpectedly, production stops and costs mount up quickly. Our industrial manufacturing clients relish our ability to specifically identify machinery solutions with industrial vibration monitoring and other services from VSC. Clients become aware of issues well in advance of equipment failure, using our vibration analysis plans to proactively eliminate machinery issues at their convenience.

Metals & Minerals

The metal and mineral industries require their rolls, pumps, fans, motors and compressors to work reliably. VSC has all the technology to perform industrial vibration monitoring, with the experience to help clients proactively identify and solve machinery faults well before they pose a problem to production.

Ships do not have the luxury of machinery failure or risking the possibility of bobbing powerlessly at sea. VSC has served many ships, including the remote monitoring of ice breakers at the North and South Poles. No matter where you are, VSC can provide you with a world class machinery condition monitoring program.

Oil & Gas

Oil and gas production fortunes are totally dependent on motors, pumps, fans, compressors, turbines, pipes and gearboxes working reliably. VSC is the industrial vibration monitoring partner that many oil and gas companies rely on. Advanced vibration monitoring services help to keep their machinery operating reliably so they can keep production running.

Pharmaceutical & Biotech

Pharmaceutical and Biotech companies rely heavily on motors, pumps, mixers, chillers, fans, compressors and centrifuges. Many depend on vibration monitoring plans to keep their equipment running reliably. There is no reason to accept reactive maintenance when VSC can see the problems coming with industrial vibration monitoring services. Issues are identified through industrial vibration analysis techniques and specific answers are provided for resolving them.

Power Generation

VSC has been helping the Power industry since its inception with vibration monitoring services and with balancing their turbines, motors, compressors, generators, exciters, fans, and pumps. Whether it is continuous remote monitoring 24/7 or remotely balancing your FD fans, VSC provides world class vibration analysis services anywhere and any time.

The paper industry depends on its motors, pumps, fans, compressors, rolls and gearboxes to operate continuously at ever faster production speeds. VSC’ machinery vibration monitoring services and industrial vibration monitoring plans make this a reality, as machine reliability is our mission. Our paper industry clients know of any machinery issues well in advance of a problem so they can proactively resolve it when it is convenient for their production schedule.

Waste Water Treatment

Waste water treatment facilities count on their machinery every day, so reliability is paramount to their success. VSC has been providing world class vibration monitoring plans remotely for these facilities across the USA. We deliver early fault detection with industrial vibration monitoring services on their pumps, centrifuges, fans, gearboxes, and compressors. In return, their maintenance has transformed from reactive to proactive driving down costs and unscheduled downtime.